Production Machining - Your access to the precision machining industrial buyer.

Issue link: https://pm.epubxp.com/i/668041

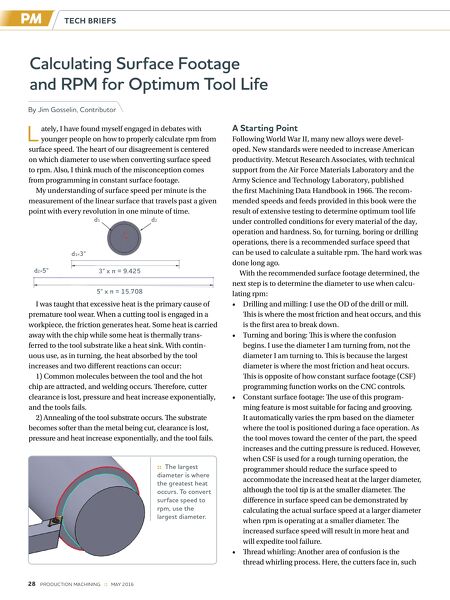

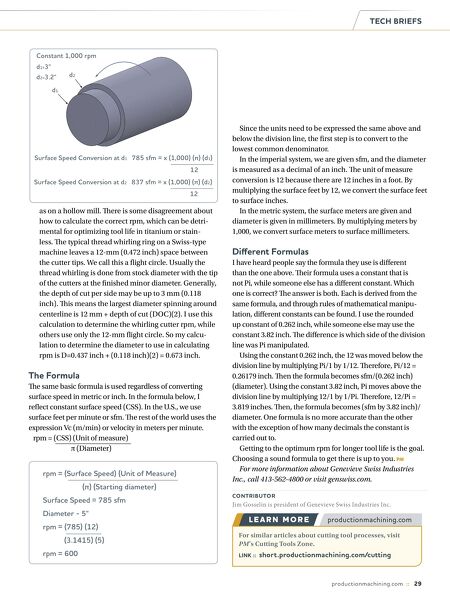

Surface Speed Conversion at d2 837 sfm = x (1,000) (π) (d2) 12 d1 d2 d1=3" d 2=3.2" Surface Speed Conversion at d 1 785 sfm = x (1,000) (π) (d1) 12 Constant 1,000 rpm rpm = (Surface Speed) (Unit of Measure) (π) (Starting diameter) Surface Speed = 785 sfm Diameter - 5" rpm = (785) (12) (3.1415) (5) rpm = 600 TECH BRIEFS productionmachining.com :: 29 as on a hollow mill. Tere is some disagreement about how to calculate the correct rpm, which can be detri- mental for optimizing tool life in titanium or stain- less. Te typical thread whirling ring on a Swiss-type machine leaves a 12-mm (0.472 inch) space between the cutter tips. We call this a fight circle. Usually the thread whirling is done from stock diameter with the tip of the cutters at the fnished minor diameter. Generally, the depth of cut per side may be up to 3 mm (0.118 inch). Tis means the largest diameter spinning around centerline is 12 mm + depth of cut (DOC)(2). I use this calculation to determine the whirling cutter rpm, while others use only the 12-mm fight circle. So my calcu- lation to determine the diameter to use in calculating rpm is D=0.437 inch + (0.118 inch)(2) = 0.673 inch. The Formula Te same basic formula is used regardless of converting surface speed in metric or inch. In the formula below, I refect constant surface speed (CSS). In the U.S., we use surface feet per minute or sfm. Te rest of the world uses the expression Vc (m/min) or velocity in meters per minute. rpm = (CSS) (Unit of measure) π (Diameter) Since the units need to be expressed the same above and below the division line, the frst step is to convert to the lowest common denominator. In the imperial system, we are given sfm, and the diameter is measured as a decimal of an inch. Te unit of measure conversion is 12 because there are 12 inches in a foot. By multiplying the surface feet by 12, we convert the surface feet to surface inches. In the metric system, the surface meters are given and diameter is given in millimeters. By multiplying meters by 1,000, we convert surface meters to surface millimeters. Diferent Formulas I have heard people say the formula they use is diferent than the one above. Teir formula uses a constant that is not Pi, while someone else has a diferent constant. Which one is correct? Te answer is both. Each is derived from the same formula, and through rules of mathematical manipu- lation, diferent constants can be found. I use the rounded up constant of 0.262 inch, while someone else may use the constant 3.82 inch. Te diference is which side of the division line was Pi manipulated. Using the constant 0.262 inch, the 12 was moved below the division line by multiplying Pi/1 by 1/12. Terefore, Pi/12 = 0.26179 inch. Ten the formula becomes sfm/(0.262 inch) (diameter). Using the constant 3.82 inch, Pi moves above the division line by multiplying 12/1 by 1/Pi. Terefore, 12/Pi = 3.819 inches. Ten, the formula becomes (sfm by 3.82 inch)/ diameter. One formula is no more accurate than the other with the exception of how many decimals the constant is carried out to. Getting to the optimum rpm for longer tool life is the goal. Choosing a sound formula to get there is up to you. For more information about Genevieve Swiss Industries Inc., call 413-562-4800 or visit genswiss.com. CONTRIBUTOR Jim Gosselin is president of Genevieve Swiss Industries Inc. For similar articles about cutting tool processes, visit PM's Cutting Tools Zone. LINK :: short.productionmachining.com/cutting